This article is available in several languages:

Represents Siemens in standardisation activities for OPC UA FX as editor for the specification and chairman of the…

Represents Siemens in standardisation activities on…

Vendor-independent communication from controller to controller

Vendor-independent communication between controllers is an important function for the future of automation and the autonomous factory. It also should be affordable and easy to implement for customers. To achieve this, it’s necessary for Siemens to cooperate with other companies to create a new standard. This can be realized with the OPC UA Field eXchange (FX) standard provided by the OPC UA Field Level Communication (FLC) initiative. They are basing this new standard on the technologies of Open Platform Communication Unified Architecture (OPC UA), a standard to exchange data platform-independently and service oriented. Architecture experts from Digital Industries Factory Automation have a significant influence on the content of this standard.

The importance of OPC UA FLC

In the year of 2018 the OPC UA FLC initiative was founded. They are part of the OPC Foundation and consist of 27 member companies that contribute with budget and even more companies who contribute with technical expertise, including Siemens.

Source: OPC Foundation.

The initiative is following the goal to offer a secure, reliable, vendor-independent and platform-independent communication from controller to controller for both Factory Automation as well as Process Automation, which was impossible before. It gives the customer more freedoms to customize their factory for their needs. The initiative’s goal is creating extensions to the already existing features of OPC UA.

| OPC Foundation The OPC Foundation is a non-profit organization founded in 1995 and has around 800 member companies from automation and IT, with one of them being Siemens. The organization creates and maintains standards for open connectivity of industrial automation devices and systems. The OPC UA FLC initiative is a part of the OPC Foundation. |

The concepts for the first specification

In November 2020 the initiative has written a Technical Paper and provided in April 2021 a first release candidate of the OPC UA FX specification covering the controller-to-controller use-case.

Especially five topics are important for the first specification: Architecture, Information Models, Offline Engineering, Logical Connections and Functional Safety.

Architecture (Clark Case, Rockwell Automation)

“Among all this time it has been a concern about how to make devices from different vendors exchange data”, Clark Case from Rockwell Automation explains. “If they wanted to exchange data with each other, often there would still have to be a gateway between translating the protocols that spoke with each other, so the information would be understood.”

This process is expensive and time intensive to implement which is why OPC UA FX offers decisive advantages to the customer.

Information Models (Paul Hunkar, Yokogawa)

OPC UA FX offers a standardized and harmonized information model allowing asset and functional management of automation components, independent of their usage; be it controller, drive, temperature sensor…, be it for factory or process automation.

“The asset model describes the physical and occasional logic because it can include firmware or aspects of the device, but the functional entity model describes the functionality that this device exposes”, says information model-chairman Paul Hunkar from Yokogawa.

Offline Engineering (Emmanuel Kolb, ABB)

Offline Engineering allows to describe the information model of an automation component and to transfer it from one engineering system to another. This works with the help of an OPC UA FX descriptor, a concept of a general descriptor idea the initiative created. The descriptor is exchanged using a file, similar to a zip-file. It allows adding manuals, drawings, and more.

Logical Connections (Georg Biehler, Siemens)

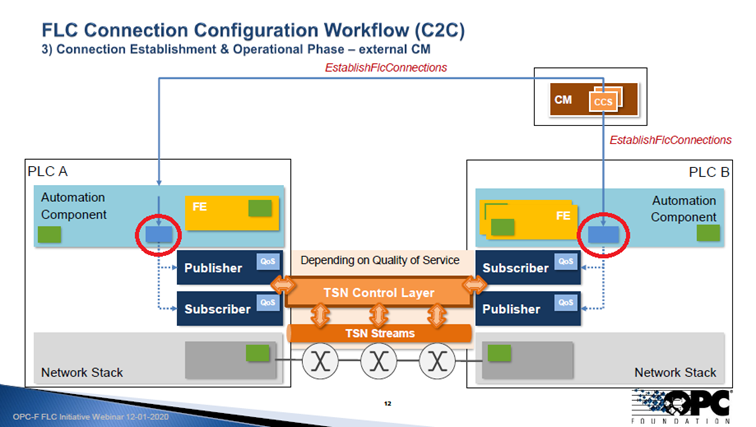

OPC UA FX supports an easy, user-friendly and standardized way of data exchange between automation components scaling from high-efficient isochronous real-time, based on Time Sensitive Networking (TSN), up to communication into the cloud based on AMQP or MQTT.

To exchange data, suitable connections are required. Logical connections allow functional entities to exchange data for controlling or monitoring purposes. The data is not limited to a certain type of data, instead, all kinds of data can be exchanged.

Real-time requirements of connections are defined using specific Quality of Services (QoS). Herewith, priorities of different data flows, guaranteed bandwidth, maximum latency or deadline requirements can be set.

“The connection endpoint is the representation of the connection inside the automation component”, Georg Biehler from Siemens explains.

Source: OPC Foundation.

OPC UA Safety (Max Walter, Siemens)

In case of functions with safety requirements all communication errors must be detected allowing the receiver to react in a safe way. Max Walter is a specialist in functional safety at Siemens AG and is responsible for functional safety within the OPC UA FLC initiative as well. “To realize safety functions, you need safety components, safe sensors and controllers and safe actuators like brakes”, Max explains. “These components have to communicate with each other. The sensor values have to be sent to the controllers and the control signal to the actuators.”

During this process several errors can occur like transmission errors or corrupt data. This could risk the safety of humans for example working alongside robots. “A quite unique feature of OPC UA Safety compared to existing safety protocols is its ability to dynamically establish safety connections during run time”, Max adds. “If we think about autonomous mobile robots which are moving within a factory and moving from one machine to another, then there can be a safety connection established as these machines are operating.”

More information of the topic

Currently, the initiative finished their first release candidate of the OPC UA FX specification covering the controller-to-controller use-case, which will be prototyped in the next months.

A final release of the OPC UA FX specification is expected for the trade fair SPS 2021 (November 2021).

To receive further information on the topic, check out the following links:

- Recording of the Webinar (OPC Foundation YouTube-Channel)

- Recording of the PI Konferenz 2021 (in German and after sign up)

“Vertikale und horizontale Kommunikation” - Recording of the IoT@Siemens Week 2021

Join the conversation!